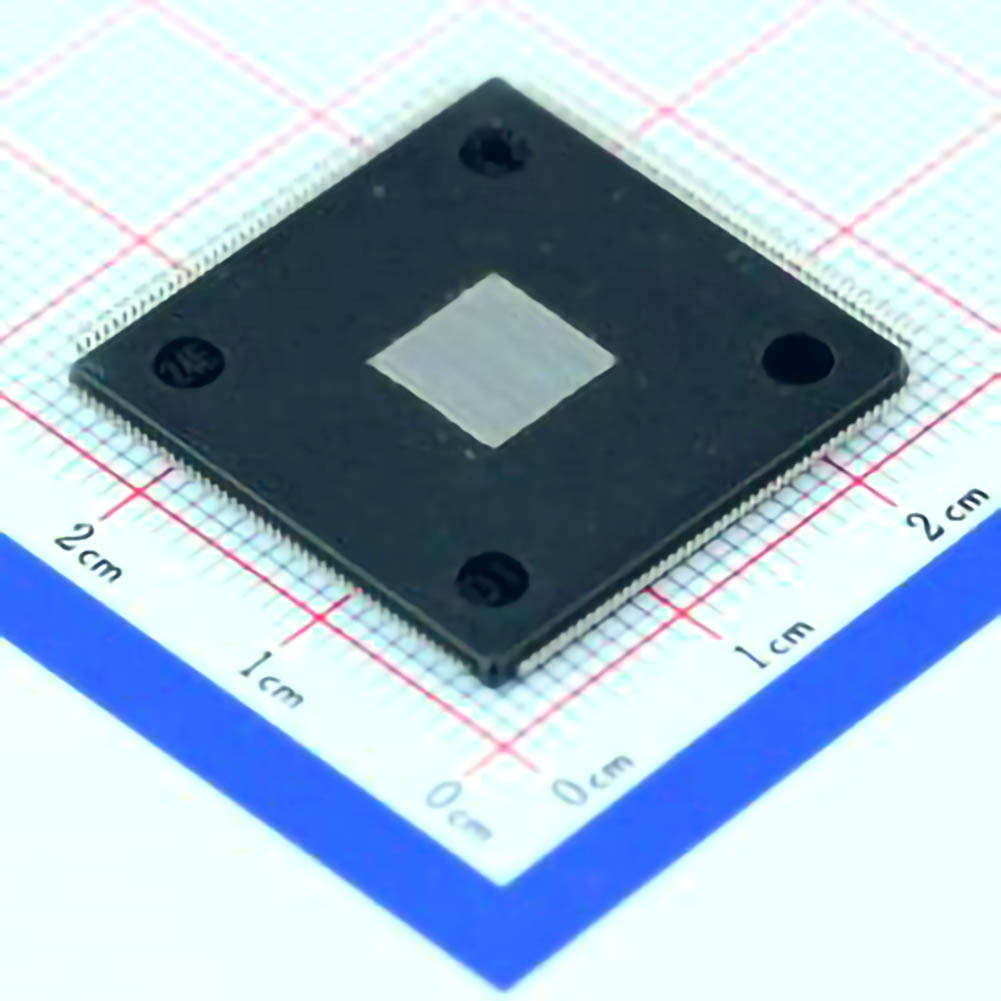

The TMS320F28335PTPQ , a high-performance Digital Signal Controller (DSC), is transforming the landscape of industrial automation by offering unparalleled processing Power , real-time capabilities, and precision. This article explores how this powerful microcontroller is driving the next generation of industrial systems, focusing on its advantages, applications, and impact.

TMS320F28335PTPQ, industrial automation, high-performance Digital Signal Controller, DSP , embedded systems, real-time control, motor control, robotics, Sensor integration, industrial systems

The Evolution of Industrial Automation and the Role of the TMS320F28335PTPQ

Industrial automation has made significant strides in recent years, with more advanced technologies being integrated into production processes to improve efficiency, safety, and reliability. As industries evolve, the need for high-performance Controllers that can handle increasingly complex tasks in real-time has become more crucial than ever. Enter the TMS320F28335PTPQ—one of the most powerful and versatile Digital Signal Controllers (DSCs) on the market.

The TMS320F28335PTPQ from Texas Instruments is specifically designed to meet the needs of demanding industrial applications, combining the high-speed capabilities of a Digital Signal Processor (DSP) with the flexibility of a microcontroller. This makes it particularly well-suited for real-time control, motor control, robotics, and industrial automation systems. Whether it’s processing sensor data, controlling motors, or managing complex algorithms, the TMS320F28335PTPQ delivers unparalleled performance and efficiency.

The Power of Real-Time Control

One of the standout features of the TMS320F28335PTPQ is its ability to provide real-time control. In industrial automation systems, real-time performance is essential for tasks that require immediate responses, such as feedback loops, sensor data processing, and motor control. The TMS320F28335PTPQ can handle thousands of calculations per second, enabling precise and timely control over various processes.

The TMS320F28335PTPQ features a 32-bit architecture with advanced DSP functionality, making it ideal for high-speed operations like signal processing, data acquisition, and communications. With a clock speed of up to 150 MHz and a high-performance computational engine, the controller can process complex algorithms in a fraction of a second, ensuring that automation systems run smoothly without delays or performance lags.

Integrating Motor Control Systems

In industrial automation, motor control is a critical component, as it governs the operation of machines and actuators. The TMS320F28335PTPQ has become a go-to solution for motor control applications due to its ability to manage both the logic and the power electronics driving the motors. The DSC integrates advanced features such as Pulse Width Modulation (PWM) outputs, high-speed timers, and multiple motor control algorithms, all of which make it an ideal choice for sophisticated motor control systems.

The device’s fast interrupt response times and extensive peripheral options enable it to seamlessly control multiple motors, making it perfect for applications like robotics, conveyor systems, and CNC machines. Its real-time control capabilities ensure that motor positions, speeds, and accelerations are adjusted precisely, improving efficiency and accuracy across industrial operations.

Power Efficiency and Reliability

In industrial automation, minimizing downtime and ensuring continuous operations are vital. The TMS320F28335PTPQ excels in both these areas due to its power-efficient design. While delivering high processing power, the DSC also consumes minimal energy, making it suitable for applications that need to run continuously without excessive power consumption.

Moreover, reliability is a key factor in any industrial setting. The TMS320F28335PTPQ has been designed to withstand harsh environments, including temperature fluctuations and electromagnetic interference, which are common in industrial automation. Its rugged design and robust processing power ensure that it can operate in demanding conditions without compromising performance.

Practical Applications and Future Outlook for the TMS320F28335PTPQ in Industrial Automation

The TMS320F28335PTPQ is revolutionizing industrial automation by enabling a range of applications that require high-performance computing, real-time data processing, and precise control. Let’s delve deeper into some of the key applications of this versatile Digital Signal Controller, as well as its future potential in shaping the next generation of industrial systems.

Precision Control in Robotics

Robotics is one of the most exciting and rapidly evolving fields within industrial automation. In a world where robots are increasingly tasked with performing intricate and high-precision tasks, the TMS320F28335PTPQ offers the processing power and control required to meet these demands. Whether it’s robotic arms used in manufacturing, pick-and-place machines, or automated assembly lines, the TMS320F28335PTPQ provides the precision and speed required to ensure accurate movements and responses.

The DSC’s high-speed signal processing capabilities allow robots to process feedback data from sensors, adjust movements in real-time, and operate with high levels of accuracy. Additionally, its ability to interface with various sensors and actuators through its multiple communication interfaces (such as SPI, I2C, and UART) makes it a versatile option for robotics systems that require complex interactions with external devices.

Enhanced Sensor Integration

The TMS320F28335PTPQ shines in applications where real-time sensor data processing is crucial. Industrial automation systems often rely on sensors to monitor various parameters, such as temperature, pressure, humidity, and vibration. These sensors generate large volumes of data that need to be processed and acted upon in real-time to ensure that systems are running smoothly.

Thanks to its advanced DSP features, the TMS320F28335PTPQ can process sensor data at high speeds and provide immediate responses. Whether it’s adjusting machine settings based on temperature readings or taking corrective actions based on pressure sensors, the DSC enables seamless integration of sensors into industrial systems. This ability to quickly process sensor data and act upon it is particularly beneficial in predictive maintenance, where the goal is to prevent equipment failure before it occurs.

Optimizing Energy Consumption in Industrial Systems

Energy efficiency is another significant advantage of the TMS320F28335PTPQ. As industries move toward more sustainable operations, the ability to optimize energy consumption is becoming increasingly important. The TMS320F28335PTPQ helps optimize energy use by enabling precise control over power-intensive components like motors and heating systems.

By implementing energy-efficient algorithms, such as variable frequency drives (VFDs) and power factor correction ( PFC ), the DSC can reduce energy consumption in industrial machinery and processes. Additionally, the real-time capabilities of the TMS320F28335PTPQ ensure that energy-saving strategies can be implemented dynamically, based on the real-time requirements of the system. This level of efficiency is vital for industries aiming to reduce their carbon footprint while improving overall productivity.

Future Outlook: The Role of the TMS320F28335PTPQ in Industry 4.0

As the world moves toward Industry 4.0, characterized by increased automation, connectivity, and smart systems, the demand for high-performance controllers like the TMS320F28335PTPQ will continue to grow. The DSC’s ability to integrate with IoT devices, handle complex data streams, and provide real-time feedback makes it a perfect fit for the smart factories of the future.

In an Industry 4.0 ecosystem, the TMS320F28335PTPQ will be instrumental in enabling smarter manufacturing systems, predictive maintenance, and automated quality control. Its ability to communicate with other devices through various protocols (like CAN, Ethernet, and Modbus) will allow it to be part of a larger, interconnected network of intelligent machines that work together to optimize production processes, improve operational efficiency, and reduce costs.

As industrial automation continues to evolve, the TMS320F28335PTPQ is poised to play a key role in shaping the future of manufacturing, robotics, energy management, and beyond. With its exceptional processing power, real-time control capabilities, and extensive integration options, the TMS320F28335PTPQ is undoubtedly a cornerstone of next-generation industrial systems.

Conclusion

The TMS320F28335PTPQ is an indispensable tool in the world of industrial automation. Whether optimizing motor control, enabling precision robotics, or processing real-time sensor data, this high-performance Digital Signal Controller is delivering unmatched performance in a wide array of industrial applications. As industries continue to push the boundaries of automation, the TMS320F28335PTPQ is well-positioned to drive innovation, efficiency, and sustainability in the industrial sector for years to come.

This two-part article explores the core capabilities and applications of the TMS320F28335PTPQ within the context of industrial automation, highlighting its role in advancing real-time control, motor management, energy efficiency, and future technological trends.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.