Identifying Common Issues with the AT42QT1011-TSHR

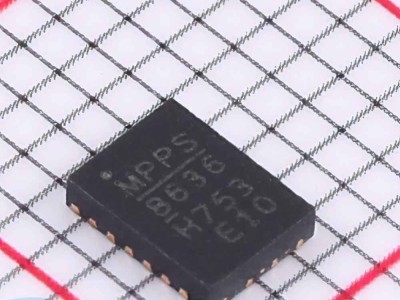

The AT42QT1011-TSHR, manufactured by Atmel (now part of Microchip), is a popular single-channel capacitive touch Sensor that is known for its low- Power operation and ease of integration into various devices. Whether you are designing a custom touch interface for your project or upgrading an existing system, the AT42QT1011-TSHR can provide a reliable and efficient solution. However, like any electronic component, it may run into issues during its use. In this section, we’ll discuss common problems you might encounter with this touch sensor and identify ways to troubleshoot them effectively.

1. No Response to Touch Input

One of the most common issues users face with capacitive touch sensors is a complete lack of response when the sensor is touched. This can be caused by several factors, including wiring errors, incorrect configuration, or issues with the sensor itself.

Possible Causes:

Incorrect Wiring: The sensor’s connections to the microcontroller or the power supply might not be correctly set up. For example, improper grounding or a missing connection to the VCC pin can prevent the sensor from working.

Faulty Sensor: While rare, the sensor itself could be defective or damaged. In such cases, checking the sensor with a multimeter can help diagnose whether it’s receiving power and functioning as expected.

Inadequate Sensor Calibration: The AT42QT1011-TSHR may require calibration, and without this step, it might not register touch inputs.

Solutions:

Check the Wiring: Ensure that all connections to the sensor are correct. Refer to the datasheet for pinouts and verify the wiring between the sensor, microcontroller, and power supply.

Test the Power Supply: Verify that the sensor is getting the required supply voltage (typically 1.8V to 3.6V) and that the ground connection is properly established.

Recalibrate the Sensor: If the sensor hasn’t been calibrated yet, follow the calibration steps outlined in the datasheet. Typically, this involves applying a reset or trigger signal to the sensor to allow it to learn the environment before use.

Test with Different Input Methods: If the sensor still doesn’t respond, try using a different touch method or surface (e.g., use a different finger or apply less pressure), as touch sensitivity can vary based on environmental conditions.

2. False Positives or Unreliable Touch Detection

Sometimes the sensor may register touches even when no user input has occurred. This problem is especially common in environments with Electrical noise, poor grounding, or improper sensor placement. False positives can also occur if the sensor is placed too close to other electronic components that EMI t electromagnetic interference (EMI).

Possible Causes:

Electromagnetic Interference (EMI): Nearby components that generate electromagnetic fields (e.g., motors, power supplies) can interfere with the capacitive touch sensor, causing erratic behavior.

Grounding Issues: Poor or incomplete grounding in the system can lead to unpredictable sensor behavior. Inadequate grounding can amplify noise, making it harder for the sensor to differentiate between actual touches and background noise.

Overly Sensitive Calibration: If the sensor is too sensitive, it may pick up small, irrelevant environmental changes, resulting in false triggers.

Solutions:

Improve Grounding: Ensure that the sensor and its surrounding components have a solid ground connection. Use short and thick wires for ground connections, and place the sensor as far as possible from noise-producing elements.

Add Decoupling capacitor s: To reduce electrical noise, add decoupling capacitors (typically 0.1 µF or 1 µF) close to the sensor’s power pins. This can help filter out high-frequency noise that may affect sensor performance.

Adjust Sensitivity: If the sensor’s sensitivity is too high, adjust it according to the datasheet recommendations or modify the settings via software. Many capacitive sensors, including the AT42QT1011-TSHR, allow users to fine-tune the sensitivity for optimal performance.

3. Intermittent Touch Detection

Another common issue is intermittent or inconsistent touch detection. The sensor may work fine at times but fail to detect touches during other instances. This could be due to environmental factors, such as temperature or humidity, or issues with the sensor’s configuration.

Possible Causes:

Environmental Factors: Capacitive touch sensors can be sensitive to changes in temperature and humidity. Excessive moisture, for example, can cause the sensor to behave unpredictably. Similarly, extreme temperatures can affect the performance of the sensor.

Power Supply Instability: Inadequate or fluctuating power supply can cause intermittent touch detection. This is particularly a concern in battery-operated systems or when using a power supply that isn’t stable.

Electrical Noise or Interference: The presence of electromagnetic interference from nearby components or external sources may be causing random noise that affects the touch sensor’s readings.

Solutions:

Control Environmental Conditions: Ensure the operating environment is within the recommended range for temperature and humidity. For example, avoid placing the sensor in areas where it may be exposed to direct sunlight, high humidity, or extreme cold.

Use a Stable Power Source: If you’re using batteries, ensure they are fresh or sufficiently charged. If you’re using an external power supply, consider adding a voltage regulator or filter to smooth out any fluctuations.

Shield the Sensor: If interference is suspected, try adding shielding around the sensor or rerouting its connections to minimize exposure to noise.

4. Sensor Not Recognizing Specific Touch Areas

In some applications, users may notice that certain areas of the sensor are less responsive than others. This can be frustrating, especially when the sensor is designed to be used across a large touch surface.

Possible Causes:

Inconsistent Electrodes: The sensor’s electrodes may have been damaged or may not be properly aligned, leading to poor touch detection in certain regions.

Poor Contact or Finger Placement: If the user is not placing their finger in the right area or not making proper contact, the sensor may not register the touch correctly.

Solutions:

Check for Damage: Visually inspect the sensor for any signs of physical damage or wear. If there are visible issues with the electrode or PCB, consider replacing the sensor.

Improve User Instructions: If the issue is related to user behavior (e.g., placing a finger too lightly or too far from the sensor), provide clearer instructions on how to use the device correctly. You may also consider modifying the firmware to accommodate different touch patterns.

Advanced Troubleshooting for the AT42QT1011-TSHR

While the first section covered common issues and straightforward solutions, some problems might require deeper investigation and more advanced techniques. In this part, we’ll dive into more complex troubleshooting steps that may help resolve persistent or rare issues with the AT42QT1011-TSHR.

1. Incorrect Output Signal

Sometimes, the AT42QT1011-TSHR may operate correctly but output incorrect signals to the microcontroller. This can be especially troublesome when using the sensor to trigger specific events or communicate with other devices.

Possible Causes:

Incorrect Configuration or Firmware Settings: If the output signal configuration or communication protocol isn’t set up correctly, the sensor might send invalid or unexpected data.

Clock or Timing Issues: The sensor relies on precise timing to work correctly. If the timing is off due to improper clock configurations or delays, the output may become unreliable.

Signal Integrity Problems: If the signal from the sensor is too weak or noisy, it may fail to be recognized correctly by the microcontroller.

Solutions:

Review Firmware Settings: Double-check your code and configuration settings. Ensure that the sensor is configured to use the appropriate communication protocol (e.g., I2C, SPI) and output format.

Check Clock Configuration: Verify that the clock settings for both the sensor and the microcontroller are correct. Look for any discrepancies in clock speeds or timing settings.

Improve Signal Integrity: Add a pull-up resistor to the communication line (if necessary) or use a logic level converter if there’s a mismatch in voltage levels between the sensor and the microcontroller.

2. Temperature or Humidity-Related Sensitivity Changes

Capacitive touch sensors like the AT42QT1011-TSHR can be sensitive to temperature and humidity changes, which may cause unexpected behavior. While this is a known limitation of capacitive sensors, it can still present challenges in applications requiring consistent performance under varying conditions.

Possible Causes:

Environmental Sensitivity: High humidity or rapid changes in temperature can affect the sensor’s ability to detect touch reliably.

Material Properties: The sensor’s touch sensitivity can be affected by the materials that are in contact with the touch surface. For example, certain materials may cause higher capacitance, leading to false positives or reduced touch detection.

Solutions:

Compensate for Environmental Factors: Consider implementing a temperature or humidity compensation algorithm in the firmware. This algorithm could adjust the sensor’s threshold or sensitivity based on environmental inputs.

Use a Protective Coating: If moisture is an issue, applying a protective coating or encapsulation to the sensor can help prevent environmental factors from affecting its performance.

3. Upgrading to Advanced Models

If troubleshooting fails to resolve some of the persistent issues, it might be worth considering upgrading to a more advanced or different capacitive touch sensor model.

Possible Causes:

Limitations of the AT42QT1011-TSHR: While the AT42QT1011-TSHR is a versatile and efficient sensor, its limitations in terms of size, sensitivity, and environmental robustness might become apparent in some applications.

Solutions:

Upgrade to a Higher-Performance Model: If your application requires more channels, higher sensitivity, or better environmental tolerance, consider upgrading to a more advanced sensor from the same product family or other manufacturers.

Conclusion

The AT42QT1011-TSHR is a powerful capacitive touch sensor that can offer excellent performance in a variety of applications. However, as with any electronic component, it can experience issues that may hinder its functionality. By following the troubleshooting steps outlined in this article, you can identify and resolve common problems such as no response, false positives, intermittent detection, and more. By carefully examining the wiring, power supply, and environmental factors, you can ensure the sensor performs optimally and integrates seamlessly into your project.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.